HGV Trailer Services

Trailer Safety Inspection

The latest DVSA Guide to Maintaining Roadworthiness (GTMR) has raised the expected standards for the maintenance and associated documentation of your HGV trailer fleet (also known as Lorry or Truck trailers), further improving safety and efficiency.

The Trailer Safety Inspection service offers a convenient mobile, on-site or en-route solution for assessing and documenting the condition of a trailer for full compliance with GTMR Section 4.2 – Safety Inspection Intervals or as an Intermediate Top-Up Check to provide operators with an extra layer of safety confidence in-between full Safety Inspections.

| Service | Suitable for |

|---|---|

| Mobile Trailer Safety Inspection | • Trailers Fitted with EBPMS. • Trailers requiring a full Trailer Safety Inspection to comply with GTMR Requirements. |

| Mobile Trailer Intermediate Top-Up Check | • Operators requiring extra confidence and documentation to assist with GTMR best practices in-between full Safety Inspections. • Trailers NOT Fitted with EBPMS. • Trailers subjected to arduous use. |

Operator Compliance Risk Score (OCRS)

Regular trailer inspections and detailed documentation demonstrate proactive maintenance to satisfy GTMR requirements, which in turn logically reduces Annual Test failures and roadside defects. This combination lowers your Operator Compliance Risk Score (OCRS) and minimises potentially unnecessary DVSA scrutiny, keeping your trucking fleet compliant and operational.

Mobile Trailer

Safety Inspection Include

1. Mobile Service: Convenient service performed at your premises to minimise downtime of your fleet asset.

2. Physical Condition Assessment: Visual inspection of the trailer’s structural integrity, including the chassis, body, and coupling mechanisms, for damage, wear, or corrosion.

3. EBPMS Review: Inspect and summarise recent data recorded by the Electronic Braking Performance Monitoring System of the trailer.

4. Brake System Check: Inspect the brake components, including air lines, reservoirs and actuators for leaks, damage, or wear. Observation of the primary braking mechanism to verify correct movement and function.

5. Wheels and Tyres: Examine tyres for tread depth, pressure, and signs of damage. Check wheels for cracks or other structural issues.

6. Suspension System: Inspect suspension components, such as springs and shock absorbers, for wear or damage.

7. Lighting and Electrical Systems: Verify that all lights, indicators, and electrical connections are operational and meet legal requirements.

8. Load Security: Ensure that load restraints and securing mechanisms are intact and capable of safely holding cargo.

9. Documentation: Record results in a safety inspection report, which becomes part of the trailer’s maintenance history to comply with GTMR Safety Inspection requirements.

Mobile Trailer

Intermediate Top-Up Check Includes

1. Mobile Service: Convenient service performed at your premises to minimise downtime of your fleet asset.

2. Physical Condition Assessment: Visual inspection of the trailer’s structural integrity, including the chassis, body, and coupling mechanisms, for damage, wear, or corrosion.

3. Brake System Check: Inspect the brake components, including air lines, reservoirs and actuators for leaks, damage, or wear. Observation of the primary braking mechanism to verify correct movement and function.

4. Wheels and Tyres: Examine tyres for tread depth, pressure, and signs of damage. Check wheels for cracks or other structural issues.

5. Suspension System: Inspect suspension components, such as springs and shock absorbers, for wear or damage.

6. Lighting and Electrical Systems: Verify that all lights, indicators, and electrical connections are operational and meet legal requirements.

7. Load Security: Ensure that load restraints and securing mechanisms are intact and capable of safely holding cargo.

8. Documentation: Record results in a safety inspection report to top-up the trailer’s maintenance history, which can demonstrate good practice and a proactive approach to the maintenance and safety of your fleet.

| Trailer Safety Inspection | Intermediate Top-Up Check | |

|---|---|---|

| Mobile Service | ✔ | ✔ |

| Physical Condition Assessment | ✔ | ✔ |

| EBPMS Review | ✔ | — |

| Brake System Check | ✔ | ✔ |

| Wheels and Tyres | ✔ | ✔ |

| Suspension System | ✔ | ✔ |

| Lighting and Electrical Systems | ✔ | ✔ |

| Load Security | ✔ | ✔ |

| Fully Documented | ✔ | ✔ |

| A method to demonstrate a proactive approach to the maintenance and safety of your fleet. | ✔ | ✔ |

| Comply with GTMR Safety Inspection Requirements as per April 2025 Amendments. | ✔ | — |

Further Exploration of GTMR

| Operating Conditions | Expected Frequency of Safety Inspections |

|---|---|

| A. Lightly Loaded Vehicles – Easy Operating Conditions | 10-13 weeks |

| B. General Haulage – Trunking | 6-10 weeks |

| C. Arduous Work – Constant Heavy Loads | 4-6 weeks |

| D. Off Road – Difficult Conditions | 4 weeks |

| E. Vehicle / Trailer 12 Years or Older | 6 weeks |

(Correct as of 17/04/25)

The Guide to Maintaining Roadworthiness (GTMR) on page 31 indicates how often you should conduct a safety inspection on your trailers to keep them safe and roadworthy.

If your truck trailers work in tough conditions, or are an older trailer, you may need to inspect them more often.

From April 2025, it is expected that HGV lorry trailers have at least four laden roller brake tests per year or have an Electronic Braking Performance Monitoring System (EBPMS) fitted.

As per section 2 of the GTMR, the trailer operator is responsible for ensuring the vehicles and trailers that they operate are kept in a safe and roadworthy condition.

Clarification of April 2025 GTMR Amendments

To follow best practice and comply with legislation there is an expectation that every safety inspection will now include a brake performance assessment which can be conducted in two ways:

1. Using an Electronic Brake Performance Monitoring System (EBPMS)

2. Using a Roller Brake Tester (RBT).

If an EBPMS is not used, the guide expects a laden (typically to an industry standard 65%) brake performance test, conducted a minimum of every 13 weeks / 4 times a year, however the Annual MOT Test can count towards one of those inspections. Although, the required frequency of safety inspections will increase depending on the trailer operating conditions.

April 2025 GTMR Amendments

Planned vs Urgent Repair Work

A trailer that fails the Annual MOT Test means that the truck trailer cannot legally be used on the road until repairs are completed to make it roadworthy again.

An unexpected Annual MOT Test failure in your trailer fleet could create a costly disruption for your business, both in terms of the time and money required to resolve the issue and the potential loss of revenue due to trailer downtime. This downtime may increase even further if the repair workshop is already at capacity and cannot conduct repairs on your trailer quickly. This unscheduled downtime may in-turn negatively impact your customer-relations in the logistics chain.

In contrast, regular safety inspections can identify potential issues that affect the Roadworthiness of the trailer before they become critical and before the Annual MOT Test is due, which then allows you to schedule repairs at your convenience. This minimises trailer downtime, saves time and money through planned repairs vs urgent repair work, reduces unnecessary stress on your logistic chain and ultimately keeps your operations running smoothly with satisfied customers.

This service from Safe Momentum can assist operators meet DVSA best practices to identify issues early, provide extra detailed documentation to assist towards with GTMR guidelines, reduce the risk of MOT failures and ensure your trailers remain safe and operational with minimal disruption.

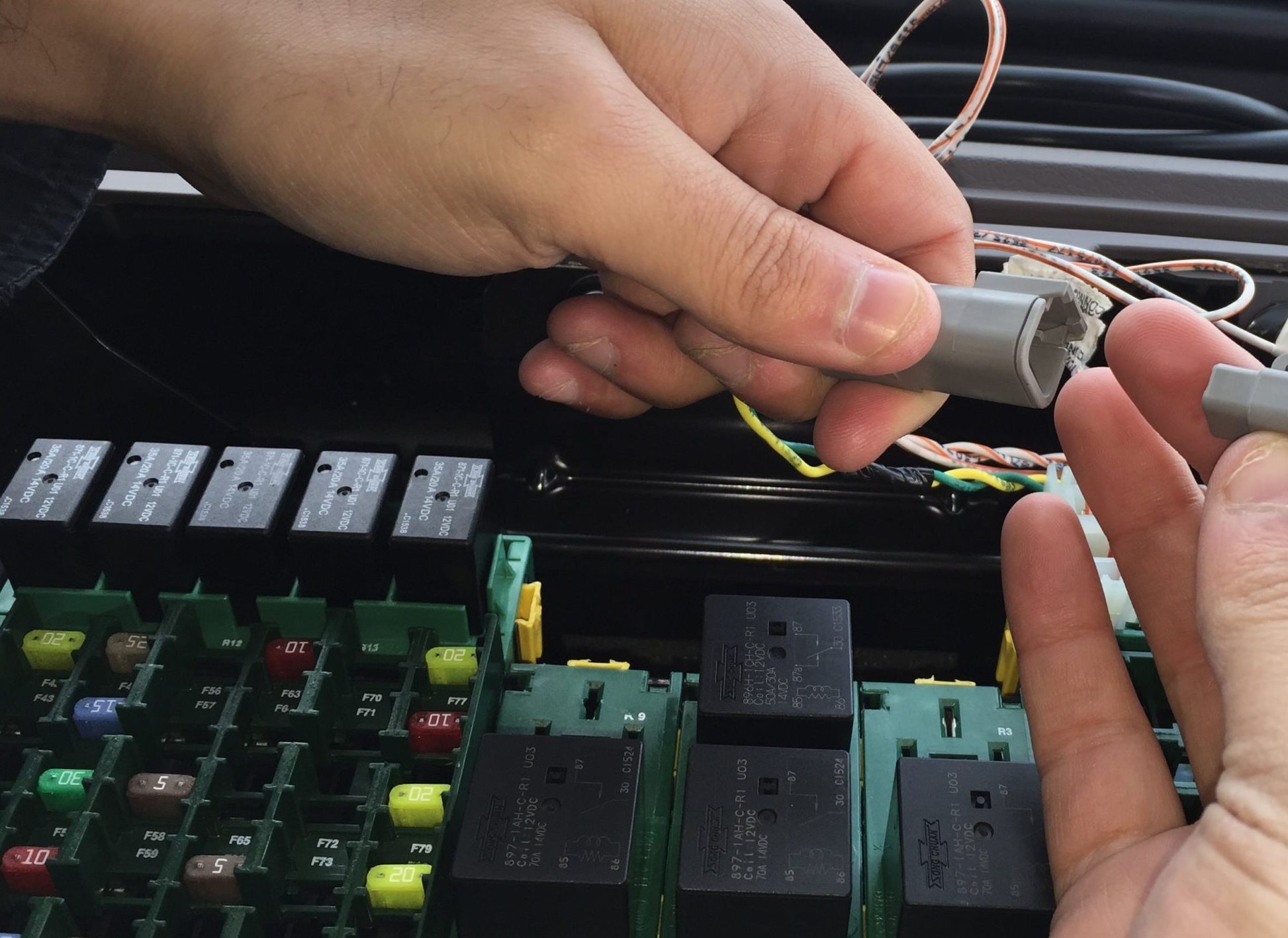

Trailer Electrical Repairs and Upgrades

A range of electrical / wiring services are available and performed on-site at your convenience to minimise the downtime of a fleet asset and avoid time-sapping journeys to the workshop.

Repairs

Upgrades